Promat Academy

Notebook Production with Erato

Notebooks are an integral part of our daily life. We use them for taking notes in school, keeping a diary, or recording our ideas. Have you ever wondered how these daily products are manufactured? Here are the secrets of notebook production in the Erato factory.

Paper Selection: The first step in notebook production is choosing quality paper. Different types of papers are preferred depending on the purpose of the notebook. For example, while thick and smooth paper is chosen for sketchbooks, thin and writable paper is preferred for daily diaries.

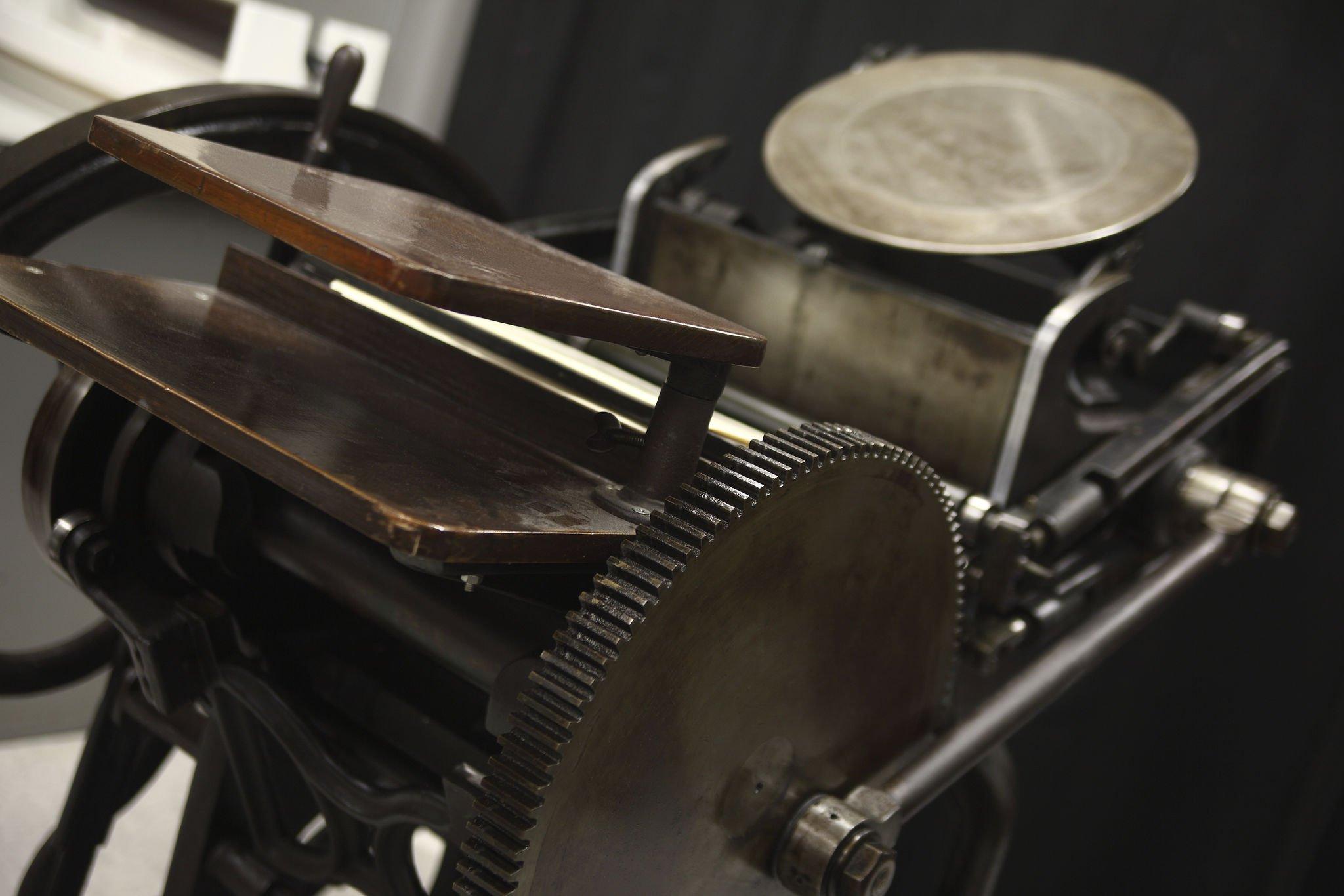

Cutting and Folding: The selected paper arrives at the factory in rolls. These rolls are cut in special machines and brought to the desired size. Then, the papers are folded to create the pages of the notebooks. A specific arrangement is made based on the number of pages in each notebook.

Stitching and Binding: After the notebook pages are folded, they go through stitching and binding. This step forms the internal structure of the notebook. Pages are either stitched together or bound with wire or adhesive. This step strengthens the durability and structure of the notebook.

Cover Production: The covers, which are the external part of the notebooks, can be made from various materials. Cardboard, leather, fabric, or plastic covers determine the appearance and durability of the notebook. Covers are generally produced using special cutting machines and gluing processes.

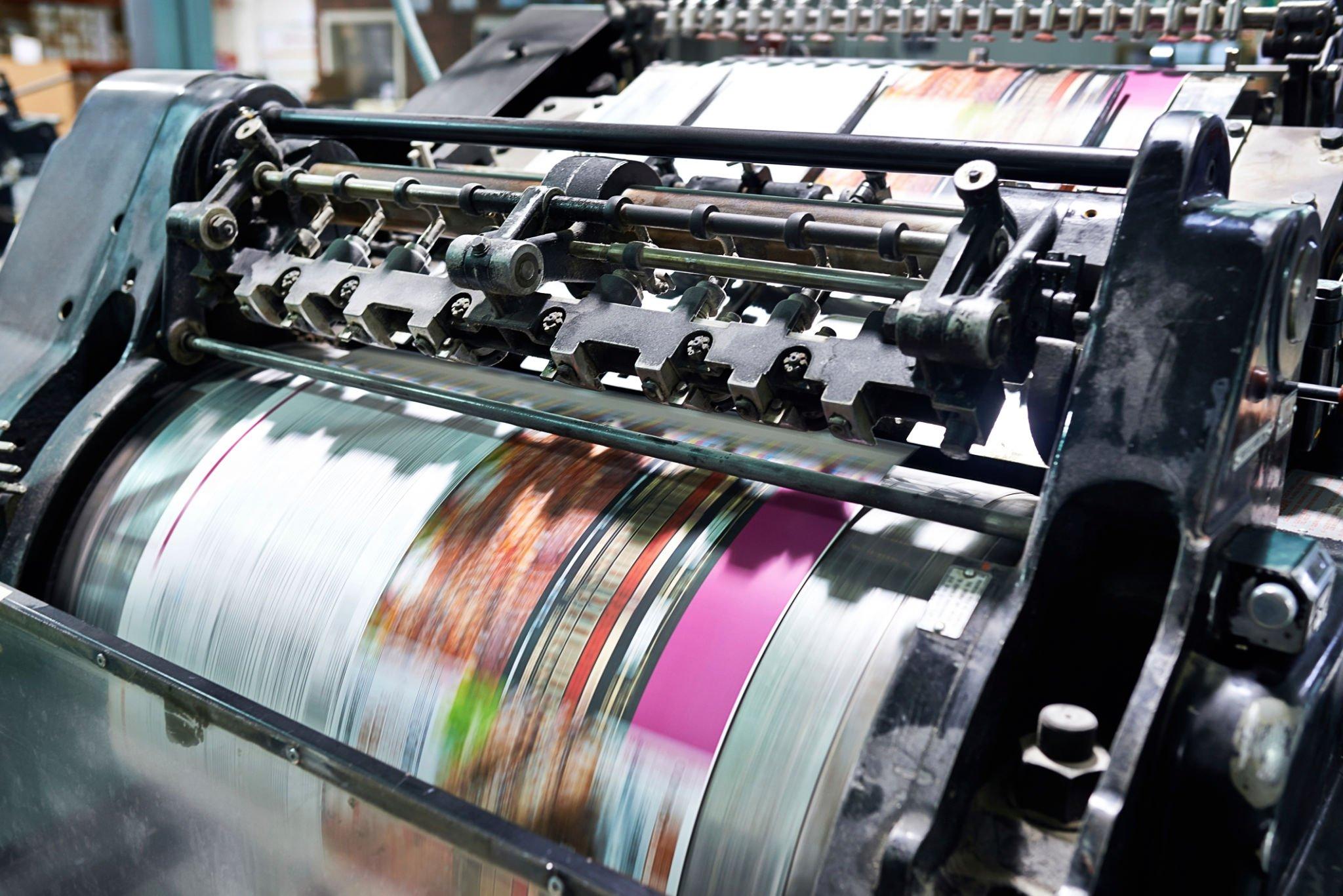

Printing and Design: Printing on the notebooks or adding special designs is an important part of personalization. In the factory, special printing machines and digital technologies are used to add patterns, texts, or images to the notebooks.

Quality Control: The final stage of the production process is quality control. The quality and integrity of each notebook are examined. If any deficiencies like missing pages, printing errors, or cover defects are found, those notebooks are corrected or discarded.

Packaging and Distribution: Finally, the produced notebooks are packaged and prepared for distribution. They are sent to retail stores or online sales platforms. They are protected until they reach the consumer.